Cardboard

Cardboard is a versatile textile that is establish inward about every household in addition to business worldwide. It has been praised for its insulating ability, merely exclusively on a pocket-sized scale. Still, when something is and then affordable too freely available, it’sec slow to wait at how we can function it for larger-scale applications.

However, before you lot stuff your walls alongside broken-downwards empty boxes, at that place are several factors you lot involve to consider.

Cardboard has insulating abilities merely its vulnerability to mold, wet, burn down, in addition to ripping way that it is not an acceptable insulation material. However, when processed, cardboard becomes a well-known as well as acceptable form of insulation known equally cellulose.

Cardboard Has Insulating Properties

Cardboard is made from cellulose or wood fiber. Considering that both forest in addition to cellulose are splendid insulators, cardboard tin effectively continue heat in or out of a structure.

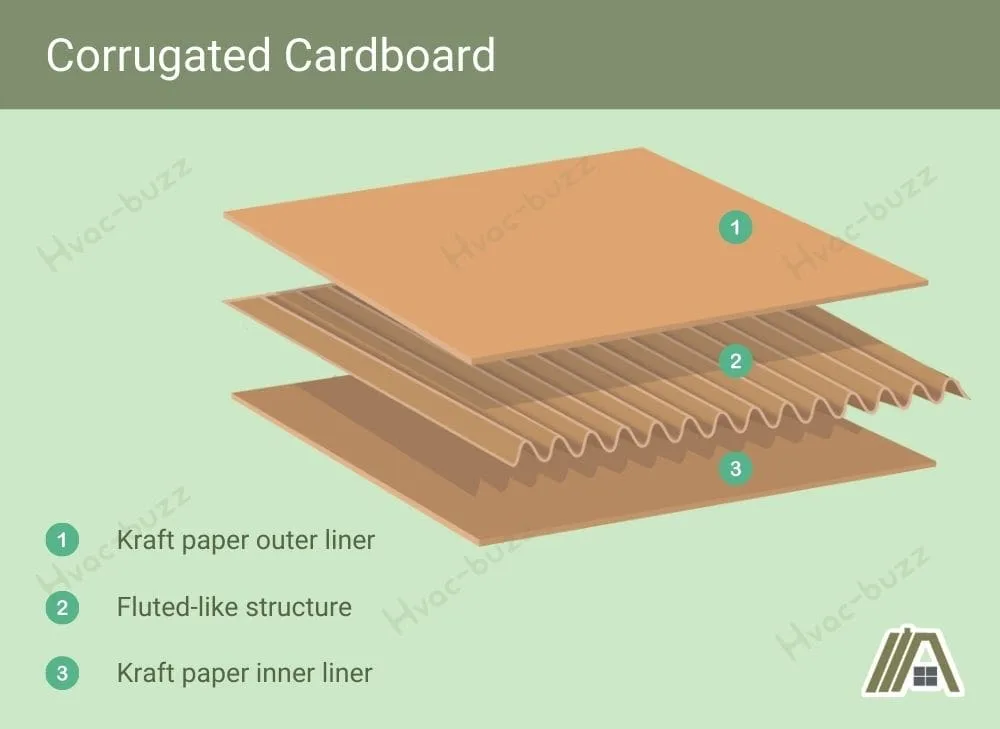

Corrugated cardboard normally has a fluted-like structure comprising layers of kraft paper alongside air pockets trapped in between.

These tightly packed fibers make air pockets that forbid heat from transferring inwards the same style every bit the air pockets inward fiberglass.

The R-value of cardboard ranges from less than R-0 to R-four per inch, depending on who y'all enquire. From nearly R2.five to R4, yous are reaching the same thermal resistive capability every bit proper insulation fabric.

However, spell cardboard can be a comparatively proficient thermal insulator, it may non always live the best selection for all insulation needs. This is because it besides has approximately less desirable qualities, which nosotros’ll discuss in the adjacent section.

Cardboard Is Not Appropriate for Insulating a House

Cardboard tin can provide roughly insulation only is not appropriate for insulating a house as it is non designed to live a long-term solution too volition rapidly deteriorate inwards well-nigh environments.

Detailed below are roughly factors that make it less suitable for insulation.

Moisture

Cardboard comprises newspaper fibers pressed together in addition to held in home alongside adhesives. The paper fibers are porous in addition to highly absorbent, making them susceptible to moisture absorption.

When cardboard absorbs moisture, the adhesives that hold the fibers together weaken, causing the cardboard to disintegrate in addition to go structurally unsound.

The cardboard may disintegrate, bend out of form, as well as shift. If used as insulation, this would effect inwards the insulation compressing, violent and splitting, in addition to/or falling down.

Aside from that, the porous nature of cardboard tin make drying difficult. As cardboard dries slow in humid climates, it may never completely dry out out, making it unusable.

Mold

As mentioned, cardboard is primarily made from cellulose fibers. When these are broken down, it becomes an ideal food beginning for mold in addition to other fungi.

When the reason for interruption down is wet, another not bad element for encouraging mold increase, it’s almost guaranteed that damp cardboard volition get moldy.

Mold increase can drive various wellness concerns, including respiratory and allergic reactions. It besides weakens the structural integrity of a building and may Pb to costly repairs.

Fire Risk

Cardboard is highly combustible. Below is a video of a cardboard burn down examination.

When used equally insulation, cardboard tin make a potential burn down hazard if it comes into contact amongst a estrus beginning, electric wires, or an open up flaming, all of which are commonly encountered inward a domicile.

Once ignited, the cardboard insulation is in a position to readily spread the burn throughout the house. Worse nevertheless, it may burn unnoticed within the walls. This agency that past the fourth dimension you lot figure out at that place is a burn, the damage to the construction of the dwelling may be extreme.

Ripping/Tearing

Even when it’second non wet, cardboard is nonetheless prone to ripping together with vehement, which tin can compromise its power to provide insulation.

The newspaper pulp making upwards cardboard is non a potent fabric, making them more than prone to violent and punctures. When exposed to wet or changes inwards temperature, the fibers within tin further weaken.

When cardboard rips or tears, it creates holes inward the insulation barrier, allowing oestrus to cash in one's chips through readily.

In addition, a torn slice of cardboard causes the fibers too air pockets of the cardboard to get disrupted as well as unable to insulate and keep a consistent temperature.

Cellulose Insulation Is Made up of Cardboard

While cardboard cannot be used every bit insulation, it tin can live used for insulation.

Cardboard tin be transformed into very effective and durable cellulose insulation. Many of the risks associated with using cardboard every bit insulation are minimized when it’second inwards the course of cellulose.

Cellulose product involves shredding the cardboard into pocket-sized pieces using a hammermill.

The pieces are treated with boric acid/pulverisation, which guards against mold increase equally the chemical contains natural anti-fungal properties. This treatment minimizes the take a chance of mold growing on the insulation.

Boric acid likewise industrial plant as a burn-retardant past forming a glassy layer on the surface of cellulose when exposed to high temperatures. This layer helps to protect the cellulose from catching burn too burning, which cardboard inward its natural land cannot offering.

This treatment is also effective at combating the issue of moisture. While cellulose insulation is non H2O-resistant, it’sec still a neat insulation pick because of its power to easy absorb in addition to wick moisture.

This characteristic allows it to maintain its insulating properties even when exposed to moisture (this does non brand wet insulation acceptable to leave).

In the terminal phase, cellulose is mixed alongside a binding agent that causes the fibers to interlock. This interlocking creates a dense, durable production that eliminates ripping in addition to tearing risks.

In improver, cellulose insulation is ordinarily in unloosen-make full form, which means that ripping in addition to violent are not every bit big of a job.

Sources

https://en.wikipedia.org/wiki/R-value_(insulation)

https://www.ehss.vt.edu/programs/FLS_fire_prevent.php

Comments

Post a Comment